The new G-MAX forage wagon builds on our decades of experience to bring you an industry leading wagon packed with exciting new features and upgraded technology from the best in the business so that you can feed out precisely, and reliably, whenever you need to.

Simple to use and easy to maintain while delivering exceptional performance, the G-MAX wagon is designed to handle all feed types, including grass, maize, whole-crop cereals, silage, and both long and precision-cut round or square bales, catering to farms of all sizes.

Choose from a broad range of options and accessories like wireless weighing and feed rate automation for precision feeding.

Watch our video where Matt takes you through the key features of the G-MAX wagon.

Strong uprights and corrosion proof stainless panels have been proven for decades to be durable and the best protection against acidic and abrasive silage

Calibrated link chains are unbeatable in harsh silage conditions, compared to lower strength roller chains which will corrode and seize. Our 13mm high tensile calibrated link chains have a tested breaking strength of 24.5 tonnes per chain for exceptional reliability. This gives a massive 49 tonnes of chain strength in every wagon. Large diameter high tensile chain sprockets are designed for high torque, maximum chain engagement, and low wear

High quality powerful gearboxes provide loads of torque for the floor and elevator power transmissions

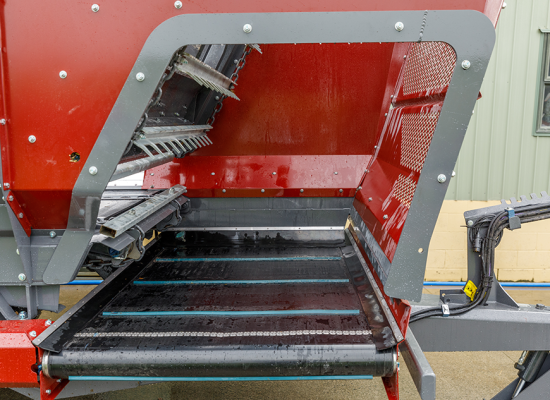

Choose from a rubber belt or roller chain and slat side delivery conveyor. The standard width is 1200mm wide to handle all types of feed, including large square bales

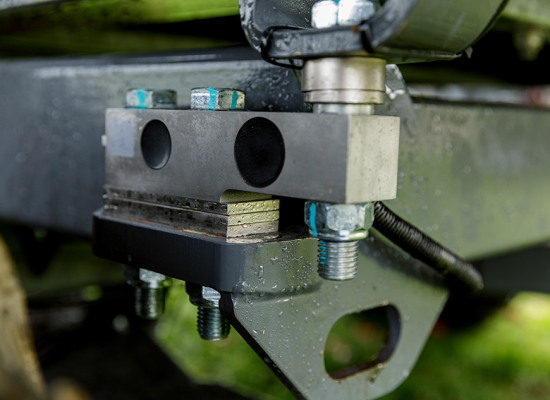

All wagons are ‘scale-ready’ with a double chassis and can have electronic load cells fitted for mobile weighing to improve your feeding accuracy and feed management

8mm heavy duty galvanised elevator bars have an aggressive tearing action to handle the toughest loads. UHMWPE plastic slides for the elevator bars for quiet and smooth running

The heavy-duty see-through back gate includes crash lock for load reversing, and a safety cover for the floor chains. It can be held open with a stay for maintenance access

The drawbar is narrow for tight turning and the swivel hitch is bolted on for easy replacement. Easily add a hydraulic jack or quick hitch stand

The mesh front screen gives the operator great visibility to the load and through the wagon for reversing

Over-sized hubs have sealed bearings, and can be swapped out for brakes or completely replaced if damaged. Heavy duty walking beam axles with replaceable Vesconite™ pivot bushes

Technology

Wireless Technology (optional)

G-MAX WIRELESS SCALES AND FEED RATE AUTOMATION

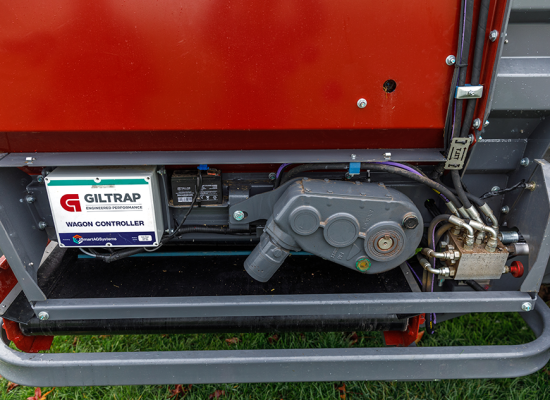

Our wireless weighing and feed rate control technology was the first of its kind on forage wagons and relays wagon data to the display mounted in the tractor or a smartphone. Designed and manufactured specifically for Giltrap forage wagons, the latest G-MAX system builds on years of experience and proven in-field reliability, using the latest technology.

You have two user display choices. Both use a wireless connection with a huge operating range of up to 100 metres, or line of sight.

Either choose the CANBUS 7-inch touch screen controller with an intuitive layout and responsive touch controls. This lets you monitor weight changes and make informed decisions from the tractor seat. The touch screen mounts inside the cab and ensures accurate loading and feed management, no matter what the weather conditions are. The on-board weighing system eliminates guesswork, with the scales and feed rate controls at your fingertips while you’re loading and operating the wagon.

Alternatively, if you don’t need electronic rate control, choose a lower-cost simplified system which displays the scale weight on your own phone or tablet. Either way, adding scales will improve your feed management and give you confidence that the correct ration portions are fed out.

The robust scale design is configured with either 4 or 6 industrial shear beam load cells and heavy-duty mounts for durability and long life. Bespoke stainless steel convex/concave pivot washers ensure accurate scale readings on the move.

GREAT TECHNICAL FEATURES INCLUDE

CANBUS TOUCH SCREEN AND PHONE DISPLAY SYSTEMS

* Programmable automatic shutdown function to conserve the life of the battery on the wagon

* Automatic fast charging of the wagon-mounted 12 volt battery

* Easily accessible electronics junction box for servicing and upgrades

* The controller module on the wagon has LEDS for simple user information and diagnostics

* TARE and GROSS scale functions at your fingertips

* Huge wireless range of up to 100 metres

CANBUS TOUCH SCREEN SYSTEM

* Compact RAM mount in the tractor cab

* The touch screen can be shifted between tractors with the addition of a second RAM mount and power loom

* Rate control and weighing modules can be fitted any time as an upgrade

* Remote technical support by Giltrap on your controller in the field. Our technical support team can access your control system with your permission, to troubleshoot and install upgrades

CHOOSE A MODE TO SUIT YOUR FARM

Wireless Scales With Manual Feed Rate Control

– Available with either the full CANBUS touch screen system or the phone-based display. The load in the wagon is displayed in kg with tare and gross scale functions at your fingertips, and the feed rate is controlled manually on the hydraulics. Requires load cells.

Wireless Electronic Rate Control Without Scales

– Only available on the full CANBUS touch screen system. Upgrade from manual control so that the feed rate can be adjusted with the controller from the tractor seat on the move – particularly useful for feeding out large bales, where the rate needs to be changed often. Requires a solenoid valve. Load cells optional.

Wireless Scales And Fully Automatic Feed Rate Control

- Only available on the CANBUS touch screen system. Upgrade to wireless scales with three different feed rate control modes. The load in the wagon is displayed in kg with scale functions at your fingertips. To feed out simply enter a percentage feed rate, or the amount you want to feed in kg, or your total feed run length and how much you want to feed out. The wagon does the rate control calculation and evenly discharges the load as required, automatically shutting off at the end of the run to eliminate over-feeding.

NEW - Giltrap G-Max Forage Wagon Specifications

| G-MAX9 | G-MAX11 | G-MAX13 | G-MAX16 | G-MAX21 | G-MAX25 | |

|---|---|---|---|---|---|---|

| Overall length (m) | 6.10 | 6.10 | 7.39 | 8.36 | 9.33 | 9.33 |

| Overall width (m) | 2.69 | 2.69 | 2.79 | 2.79 | 2.98 | 2.98 |

| Overall height (m) | 2.76 | 2.94 | 2.93 | 3.00 | 3.23 | 3.52 |

| Loading height (m) | 2.47 | 2.65 | 2.64 | 2.72 | 2.94 | 3.25 |

| Tare weight (kg) | 3250 | 3430 | 4050 | 4630 | TBC | TBC |

| Cubic capacity (m3) | 9 | 11 | 13 | 16 | 21 | 25 |

| Conveyor belt width (mm) | 1200 | 1200 | 1200 | 1200 | 1200 | 1200 |

| No. of floor chains | 2 | 2 | 2 | 2 | 2 | 2 |

| Chain size - floor and elevator (mm) | 10 | 13 | 13 | 13 | 13 | 13 |

| Load cells (kg) | 4 x 5000 | 4 x 5000 | 6 x 5000 | 6 x 5000 | 6 x 5000 | 6 x 5000 |

| Axle size (mm) | 60 (6 stud) | 70 (6 stud) | 70 (6 stud) | 80 (8 stud) | 90 (8 stud) | 130 (sprung) |

| Wheels | 11.5/80x15.3 | 11.5/80-15.3 | 400/60-15.5 | 400/55-22.5 | 500/60-22.5 | 500/60-22.5 |